(12-2018) Volvo/Renault/Mack Premium Tech Tool PTT is updated to version 2.7. Here are PPT and Dev tool free download links and released notes.

Volvo Premium Tech Tool PTT 2.7 Release Notes

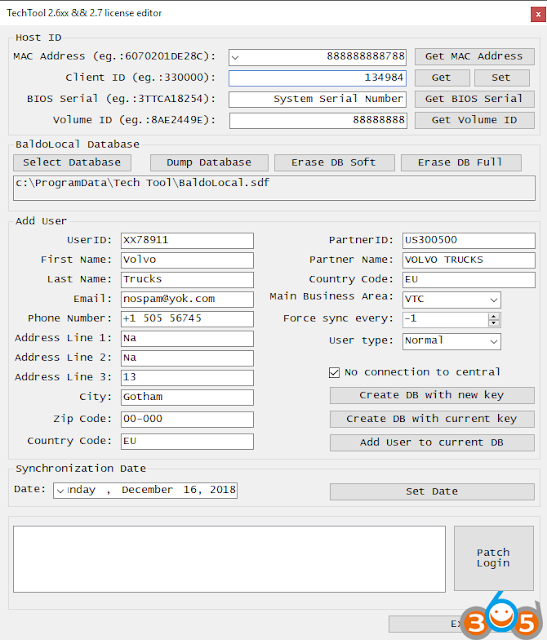

Part 1: Download Volvo Tech Tool 2.7 + Dev Tool

Premium Tech Tool 2.7.0.15 install files from Volvo server.

These are the original files, no activation.

To be able to install these, you need to make your own installer or get one from Fang88 .

Maybe someone with skills can use it to make an activator.

Used Winrar 5.60 Beta x64 to make the archive.

If the first link doesn’t work, try the second one.

Good luck!

Props to Fang88 for directing me to the files

Password: chestertechsucks

DevTool for Tech Tool 2.7

IMPORTANT: this is customer share at the mhh forumIt’s personal – No one will hold any risk of what you’ll done!Keygen, activation, installation, security issues and the like might happen to you You’re advised to have a 100% tested version, confirmed with zero issues:

Both versions can be good; you can use them with relief!

Part 2: Volvo Tech Tool 2.7 Released Notes

This news information gives you an overview of new features and changes in Tech Tool. Please take your time to read through this information carefully as it will support you in having full benefit of the tool.

For more information about functions and dialogues in Tech Tool, please see What’s new… and the Help file within the application.

- – December 5, 2018

The release is available for download in Client Update from week 49, 2018.

Corrections and changes in the release

Corrections and changes in the release are listed below:

| Description | Company |

| Operation 3711-08-03-03 ‘Data Links, Fault Tracing with Oscilloscope’ has been updated to make it easier to evaluate CAN signal disturbance. | VTC, RTC, VBC, MACK, UD, EICHER |

| NOx sensor values added in operation 25920-3/32589-08-03-02 ‘Exhaust aftertreatment system, service regeneration’. |

| Description | Company |

| Improvements in operation 25846-3/2589-08-03-05 ‘SCR System, test’. | VTC, RTC |

| The performance of operation 28308-3/2840-08-03-01 ‘Idle shutdown function check’ has been improved with new monitoring, status icons will be updated immediately opposed to a several seconds delay as it was before. |

| Description | Company |

| A new symptom has been added; speed dependent driving level. | VTC |

| Description | Company |

| Updates of calibration operation for LPOS (lane position and object sensor camera) to support new EBS in Renault. | RTC |

| Description | Company |

| Tech Tool now supports fault tracing for the new 8L engine. | UD |

| Description | Company |

| Update of wiring in fault tracing for pre-heater relay for MD8L engine. | VBC |

| Improvements and corrections to EU6 diagnostic information in operation 25456- 3/2545-08-03-02 ‘Exhaust Aftertreatment Diagnostics’. | |

| Software download and calibration operations for the Generation 2 electrical bus are now available. | |

| Fault tracing is now available for Generation 2 electrical bus for the following Electric Control Units; · Hybrid Powertrain Control Unit (HPCU) · Energy Storage Control Module (ESCM) · Powertrain Control Module (PCM) · Charging Interface Control Unit (CICU) |

| Description | Company |

| Support for Motor Grader model: G9260. | SDLG |

| Description | Company |

| Support for Crawl Excavator model: EC200E. | VCE |

| 76001-3 ‘Extended axle locking function, check’ applicable for Wheel Excavator models: EW220E and EW240E MH | |

| 38335-3 ‘Displayed Machine hours, correction’ is now also applicable for Wheel Paver model: P4370B | |

| D4J EU Stage V/US Tier 4 final support has been added for following models: · Compact Wheel Loader models: L45H and L50H. · Wheel Excavator models: EW140E, EWR150E and EWR170E · Soil Compactor models: SD115B, SD135B and SD160B · Asphalt Compactor models: DD110C, DD120C and DD140C · Track Paver models: P4820D · Crawl Excavator models: EC140E EC160E, EC180E, EC200E and ECR145E | |

| D6J EU Stage V/US Tier 4 final support has been added for following models: · Wheel Loader models: L60H, L70H and L90H. · Wheel Excavator models: EW160E, EW180E, EW205E, EW220E and EW240E MH · Track Paver models: P5110B and P6820D · Wheel Paver model: P5170B · Crawl Excavator models: EC220E and ECR235E |

| Description | Company |

| D8J EU Stage V/US Tier 4 final support has been added for following models: · Wheel Loader models: L110H and L120H · Track Paver models: P7110B and P7820D · Wheel Paver model: P7170B · Crawl Pipe Layer model: PL3005E · Crawl Excavator models: EC250E, EC300E & ECR355E | |

| D13J EU Stage V/US Tier 4 final support has been added for following models: · Wheel Loader models: L150H, L180H, L220H and L260H · Articulated Hauler models: A35G and A40G · Crawl Excavator models: EC350E, EC380E and EC480E · Crawl Pipe Layer model: PL4809E | |

| D16J EU Stage V/US Tier 4 final support has been added for following models: · Wheel Loader model: L350H · Articulated Hauler models: A45G and A60H · Crawl Excavator model: EC750E | |

| D3.8H EU Stage V/US Tier 4 final support has been added for following model: · Soil Compactor model: SD75B | |

| D3.3H EU Stage V/US Tier 4 final support has been added for following models: · Compact Wheel Loader models: L30G and L35G · Soil Compactor model: SD45B | |

| D2.6H EU Stage V/US Tier 4 final support has been added for following models: · Compact Wheel Excavator model: EW60E · Compact Crawl Excavator model: EC60E | |

| 25402-3 ‘Particulate Control Diagnostics’ applicable for all models with · D2.6H, D3.3H and D3.8H EU Stage V/Tier 4 final engines. · D4J, D6J, D8J, D13J and D16J EU Stage V/US Tier 4 final engines. | |

| Diagnostics support is added for Articulated Hauler model: A60H | |

| Diagnostics support is added for Crawl Pipe Layer model: PL3005E |

Important Information

Known issue

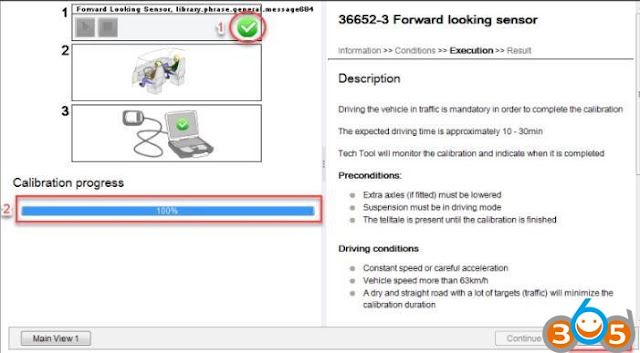

In Tech Tool 2.7.25, there is a known issue for operation 36652-3/3665-07-03-04 ‘Forward looking sensor, calibration’, selection B on road calibration. This issue affects the following products;

Products updated to comply with AEBS step 2 regulation.

- Renault & Volvo Trucks Bridge

- Renault Trucks HD

- Volvo Trucks HD

- UD Trucks HD

When the calibration has been completed and the progress bar has reached 100%, the operation does not proceed to the result view.

The calibration works, but it is not possible to display the result view. Work around

When the calibration is done;

- In Tech Tool: Verify that there is a green check tick for the

- In Tech Tool: Verify that progress bar has reached 100%.

- In Instrument Cluster: Verify that the driver assistant system is now available again in the instrument

- In Tech Tool: Click

- In the truck: Do Key Off, Key On

Volvo tech tool tech support: http://www.obdii365.com/